Kanban

Actually, Kanban means many things. Literally, Kanban is a Japanese word that means ”visual card”. At Toyota, Kanban is the term used for the visual & physical signaling system that ties together the whole Lean Production system. Most agile methods such as Scrum and XP are already well aligned with lean principles. In 2004, however, David Anderson pioneered a more direct implementation of Lean Thinking and Theory of Constraints to software development. Under the guidance of experts such as Don Reinertsen, this evolved into what David called a ”Kanban system for software development”, and which most people now simply refer to as ”Kanban”. So while Kanban as applied to software development is new, Kanban as used in Lean Production is over a half century old.

Does Kanban matter to me?

Do any of these sound familiar?

- “We’ve done Scrum for a long time now and our process improvement has levelled off. How can we take our process to the next level?”

- “Our needs and priorities shift on a daily basis”

- “We don’t like fixed-length, fixed-commitment iterations”

- “We are spending too much time planning and estimating”

If so, read on. Along with Scrum and XP, Kanban should be part of the process toolkit of any agile company. The choice of where & when to use it can only be made by you though.

How does Kanban work?

There are many flavors, but the core of Kanban means:

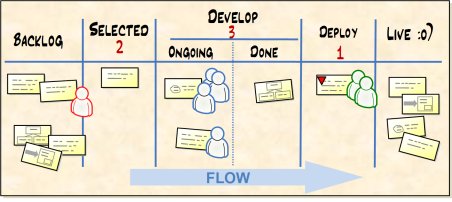

- Visualize the workflow

- Split the work into pieces, write each item on a card and put on the wall.

- Use named columns to illustrate where each item is in the workflow.

- Limit WIP (work in progress) – assign explicit limits to how many items may be in progress at each workflow state.

- Measure the lead time (average time to complete one item, sometimes called “cycle time”), optimize the process to make lead time as small and predictable as possible.

This is a direct implementation of a lean pull scheduling system. Here’s an example of a simple Kanban board, with WIP limits in red.

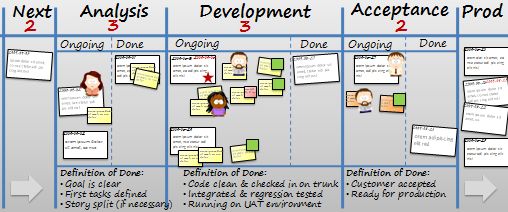

Here’s a more complex one (see Kanban kick-start example for a closer look & description)

What are the benefits of Kanban?

Some commonly observed benefits are:

- Bottlenecks become clearly visible in real-time. This leads people to collaborate to optimize the whole value chain rather than just their part.

- Provides a more gradual evolution path from waterfall to agile software development, thereby helping companies that previously have been unable or unwilling to try agile methods.

- Provides a way to do agile software development without necessarily having to use time-boxed fixed-commitment iterations such as Scrum sprints. Useful for situations where sprints don’t make much sense, such as operations and support teams with a high rate of uncertainty and variabilty.

- Tends to naturally spread throughout the organization to other departments such as HR and sales, thereby increasing visibility of everything that is going on at the company.

Can I combine Kanban with my current process?

Yes. In fact, you should combine it. In Kanban the first step is to visualize your current process, just as it is, in order to see where the bottlenecks are. Then you introduce WIP limits and start a path of evolution that may or may not modify or replace your current process over time. See “Kanban & Scrum – making the most of both”, where Henrik Kniberg and Mattias Skarin illustrate how Kanban and Scrum relate to each other.

Where is Kanban used?

Our coaches at Crisp have helped several clients use Kanban to improve their process. In fact, a surprising number of our clients have found that Kanban is an extremely useful complement (or sometimes even a replacement) to other popular agile methods such as Scrum. Typical manager comment: ”It really helps us visualize our projects and situation”. There is also an increasing number of case studies available at www.limitedwipsociety.org. Here are a few examples:

- Improving operations using Kanban, Mattias Skarin, Developerdays 2009

- David Anderson’s case study – and why lead time is best metric

- David Joyce shows how a Scrum team improves by moving to Kanban with Statistical process control data

Common misunderstandings about Kanban

- Myth: With Kanban you don’t use iterations

- Fact: With Kanban iterations are optional. Do it only if you have a need for it in your context.

- Myth: With Kanban you don’t estimate

- Fact: With Kanban estimation is optional. Do it only if you have a need for it in your context.

- Myth: Kanban is better than Scrum/XP/RUP/whatever

- Fact: Kanban is just a process tool, and there is no such thing as a universally good or bad tool. It all depends on your context. See this article for more info.

- Myth: Kanban is a drop-in replacement to Scrum/XP/RUP/whatever

- Fact: Kanban is just about managing workflow. It hardly replaces anything. What it does do, however, is drive change. In Kanban you start with whatever process you have, visualize it, introduce WIP limits, and then evolve from there.

Upcoming Kanban courses & events

We offer training courses in Kanban and Lean software development.

Case examples

Marketing

Enterprise

- Enterprise Kanban (article by Mattias) – shows how Kanban can be used to improve the full value stream

Multi team projects

- Lean from the Trenches – Managing Large Scale Projects with Kanban (book by Henrik) – shows advanced application of Kanban in a 60-person project

Operations

- Kanban & Scrum, making the most of both (book by Henrik & Mattias)

Further reading

- Kanban (book by David J Anderson)

- Kanban & Scrum, making the most of both (book by Henrik & Mattias)

- 10 kanban boards and their context (article by Mattias)

- Converting a Scrum team to Kanban (article by Mattias)

- www.limitedwipsociety.org – main Kanban resource site

- One day in Kanban land (comic strip by Henrik)

- Kanban kick-start example (template by Henrik)

- How can support and operations be Agile (slides by Mattias)

- Mattias’ blog entries on Kanban and more

- Henrik’s blog entries on Kanban and more

- Queue utilization is a leading indicator (Corey Ladas)